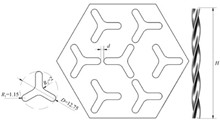

BackgroundFuel assembly is one of the key components of a nuclear reactor that significantly impacts the thermal-hydraulic performance of the pressurized water reactor. The helical tri-lobe fuel (HTF) design has a better heat transfer performance compared with the mature rod-type fuel, hence has drawn much attention and deserves to further illustrate the enhanced heat transfer mechanism of helical structure.PurposeThis study aims to employ numerical simulation to examine the single-phase flow and heat transfer properties within HTF assemblies, investigating the influence of structural parameters on flow and heat transfer.MethodsFirstly, a 7 HTF elements arranged in a triangular lattice was taken as analysis object in this study. The models of the HTF elements with various structural parameters were constructed, including different helical pitches, gap distances and ratio of lobe root arc to lobe tip arc radius (R2/R1). Then, the Integrated Computer Engineering and Manufacturing (ICEM) was adopted to generate a high-quality hexahedral structured mesh, achieving high mesh quality to accurately calculate the complex flow dynamics within the helical fuel flow field. Mesh independence check was conducted to confirm the satisfactoriness of the mesh scheme. Subsequently, ANSYS Fluent 2021R1 was adopted as the calculation platform, with the shear stress transport (SST) k-ω turbulence model and wall symmetry model being selected. The calculation model was set up with boundary conditions of a velocity inlet, pressure outlet, and uniformly heated wall surfaces. Finally, the essential thermal parameters, such as secondary flow velocities, vorticity of the cross-section, temperatures, and heat transfer coefficients of helical fuel flow field with different spiral shapes during the flow and heat transfer processes, were extracted from simulation output to elucidate the precise influence of these structural parameters on the flow and heat transfer characteristics.ResultsSimulation results show that the helical structure of the HTF significantly augments the lateral mixing flow of the coolant and therefore intensifies the heat convection. The secondary flow intensity near the cladding surface area of the HTF is enhanced by reducing the helical pitch, and the heat transfer capacity of the HTF is improved. Meanwhile, with the decreasing of the helical pitch, the flow resistance of the coolant channel increases. However, a helical pitch exceeding 240 mm markedly amplifies fluid temperature non-uniformity and cladding surface temperature variations. Reducing the minimum distance between fuel elements can enhance the heat transfer capacity, while having little influence on the non-uniformity of fluid and cladding surface temperature. The increase of the R2/R1 of the HTF strengthens the heat transfer capacity, weakens the temperature concentration in the concave arc and increases flow resistance of the coolant channel.ConclusionResults of his study provide insights into optimizing fuel assembly design for enhanced thermal-hydraulic performance and reactor safety.

BackgroundHydride is a common defect caused by the reaction of zirconium water with primary coolant in the normal operation of zirconium alloy clad tubes in nuclear power plants.PurposeThis study aims to study the effect of hydride on mechanical properties of zirconium alloy.MethodsIn this study, molecular dynamics method and third-generation charge-optimized many-body (COMB3) potential function were used. Firstly, the molecular dynamics software large-scale atomic/molecular massively parallel simulator (LAMMPS) was used to construct zirconium base models containing different hydrides. Relaxation was performed at 300 K for 50 ps. Then uniaxial stretching was performed at a strain rate of 1010 s-1 in the direction [0001] for 30 ps, which was 30% strain.ResultsThe results show that the yield strength, strain and Young's modulus of the alloy decrease with the increase of hydride density in the range of 0~1 078 μg·g-1. When the hydride density is between 1 078 μg·g-1 and 2 311 μg·g-1, the yield strength, strain and Young's modulus increase with the increase of hydride density. When the hydride density is 1 078 μg·g-1, the yield stress of the model drops to the lowest value of 7.69 GPa, which is 42.22% lower than that of the pure Zr model. The yield strain decreases to the lowest value 0.089 5, which is 39.34% lower than that of the pure Zr model. Young's modulus drops to the lowest value of 112.18 GPa, which is 8.94% lower than that of the pure Zr model.ConclusionsWhen the hydride density is in the range of 0~1 078 μg·g-1, in the elastic stage, the increase of hydride density increases the stress concentration area, which is conducive to dislocation nucleation. In the plastic deformation stage, with the increase of hydride density, the initial dislocation is more inclined to expand around the hydride. When the hydride density is in the range of 1 078 μg·g-1 to 2 311 μg·g-1, a large number of dislocations are generated due to the high hydride density, resulting in dislocation plugging.

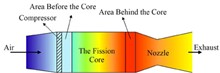

BackgroundWith the further improvement of engine thrust, specific impulse, and inherent load requirements in modern aerospace systems, nuclear thermal propulsion (NTP) technology has considerable development potential. Air-breathing nuclear thermal propulsion engines do not need to carry oxidants and chemical fuels, directly drawing air from the atmosphere, heating, and generating thrust, further reducing the inherent load of the engine.PurposeThis study aims to explore the response of air-breathing NTP reactors to flow-blockage accidents, and study the influence of blockage factors on the stability of reactor operation under different blockage ratios and positions to obtain the pre-judgment parameters.MethodsFirst of all, a cross dimensional neutronics-thermal hydraulics-mechanicals multi-physics field coupling model was established with zero-dimensional point reactor kinetics equations, one-dimensional fluid, and three-dimensional solid thermo-mechanical forms. Then, multiple verification and validation (V&V) tests were conducted to verify the correctness of the code for efficiently calculating the transient response of the system, including multiple feedback mechanisms, with a deviation of less than 5%. Finally, the response of reactor flow-blockage accidents at different degrees and positions at a blockage area rate of 0 to 100% under rated operating conditions was investigated.ResultsThe calculation results indicate that as the proportion of blockage areas increases, the limiting factor for core safety and stability shifts from temperature to blockage thrust loss, and the maximum blockage factor allowed for the engine to achieve self-stabilization generally decreases to 0.74. In large-scale blockage accidents, temperature and stress are maintained within safe levels. When the blockage factor exceeds the limit, the low total pressure behind the reactor rapidly decreases the thrust and forms positive feedback, causing engine instability. As the blockage position moves downstream, the reactor is more likely to enter an unstable state under the same blockage factor conditions. When the initial total pressure behind the reactor after blockage is less than 1.53 MPa, it can be considered that the current blockage factor of the reactor is only 15.3% at most different from the critical instability value. After organizing a large amount of data, the total pressure of 1.53 MPa behind the reactor can be considered as a pre-judgment condition for approaching instability. The value may vary under different reactor conditions, but the parameter has system conservation and consistency. Taking the allowable temperature limit and the initial total pressure behind the reactor into account, it can provide early warning for any uncontrolled flow conditions.ConclusionsSimulation results of this study provide experience for early warning and intervention of flow-blockage accidents in air-breathing nuclear thermal propulsion engine working.

BackgroundAnalog-based instrumentation and control systems in nuclear power plants (NPP) are being progressively supplanted by comprehensive digital technologies, enabling the deployment of sophisticated and efficient advanced control methodologies. Although there are studies on improving the control performance of pressurized water reactor (PWR) NPP control systems by advanced control algorithms, most of them only focus on the control system itself without considering the interconnection and coupling among multiple control systems.PurposeThis study aims to propose a setpoint decision optimization system for coordinating multiple control systems from the top level to optimize the overall control performances and achieve better task execution results.MethodsThe intelligent decision system for PWR control system was optimized based on particle swarm optimization (PSO) method. Both the decision objective function and operation constraint conditions of the intelligent decision system were proposed. Considering the actual operation of PWR, the setpoint was optimized offline and the intelligent decision operation was performed online according to the operation condition to provide the directions and amplitudes of the control targets for the underlying control systems. Subsequently, the typical operation process of the PWR NPP was taken as an example to carry out the simulation of the designed PSO-based intelligent decision-making system, and the simulation results were compared with that of traditional setpoint decision method in term of Integral of Time multiplied by the Square Error (ITSE).ResultsCompared with the control scheme using traditional setpoints, the ITSE values of average coolant temperature in primary loop, pressurizer fluid level, pressurizer pressure and steam generator fluid level obtained by optimized setpoint are decreased by 58.9%, 67.7%, 99.9% and 83.3%, respectively. The peak values are decreased by 62.4%, 3.0%, 100% and 66.3%, respectively.ConclusionsThe simulation results show that the system proposed in this study effectively reduce the ITSE and peak value of the system. The overall control performances and safety margin of the control systems of PWR NPP are improved.

BackgroundContinuous SiC fiber-reinforced SiC-matrix composites (SiCf/SiC) can be used as the fuel cladding, control rod sheath, intermediate heat exchanger, and tube components for nuclear reactor, the reliability of its joining is very crucial to the safety of nuclear energy.PurposeThis study aims to explore the microstructure and mechanical properties of SiCf/SiC brazed joints, and optimize processing of connecting SiCf/SiC with SiCf/SiC using brazing method.MethodsSiCf/SiC was firstly prepared by chemical vapor infiltration (CVI) method, and active brazing method was used to join SiCf/SiC under 850 ℃, 870 ℃, and 890 ℃ with Ag-26.77Cu-4.4Ti (wt.%) filler metal. Then, the microstructure and interfacial phase of the brazed joint under different temperatures were analyzed for a high joining performance using optical microscopy (OM), scanning electron microscope (SEM), and energy dispersive spectrometer (EDS). The mechanical properties of the brazed joint were analyzed using thermal simulated test machine.Results & ConclusionsObservation results indicate that AgCuTi filler realizes stable joining for SiCf/SiC, and the surface smoothing of SiCf/SiC is beneficial to improve the shear strength of the joint. The reaction between Ti, Si, and C becomes more intense with the increase of the brazing temperature. When the brazing temperature reaches 890 °C, the brittle phase of Ti5Si3 gradually diffuses and disperses to the brazing seam, and the reinforced phase TiC becomes the main component of reaction layer, which effectively improves the microstructure and significantly increases the strength of the SiCf/SiC brazed joint.

BackgroundIn pursuit of promoting the diversified development of energy cooperation demands among countries participating in the Belt and Road Initiative and address the demand for secure and efficient energy supply along the Belt and Road Economic Belt, Xi'an Jiaotong University has actively innovated and proposed a small modular fluoride-salt-cooled high-temperature advanced reactor FuSTAR.PurposeThis study aims to evaluate the load following capability and safety of the FuSTAR reactor.MethodsThe thermal-hydraulic modeling of the reactor body and the residual heat removal system of a small modular fluoride-salt-cooled high-temperature advanced reactor FuSTAR was conducted using conservation equations in macro form and point kinetics equations. Then, the one dimensional thermal fluid simulation program was used for modeling calculation and a constant coolant outlet temperature scheme was employed in the design of the control system for FuSTAR reactor by coupling simulation program with Simulink. Finally, the disturbance rejection characteristics and load following capability of the FuSTAR reactor were analyzed by inserting reactive disturbances and varying thermal load conditions.ResultsCalculation results show that FuSTAR demonstrates load following capability without relying on an external control system, mainly due to its inherent safety features, which allow the reactor to self-stabilize and regulate under load variations. With the adoption of a constant coolant outlet temperature control scheme, the load following capability of FuSTAR has been further enhanced. In the tests of 10% FP (Full Power) load step change and 5% FP·min-1 rate linear load rise and fall, the overshoot of nuclear reactor power is strictly controlled within 5%.ConclusionsResults of this study indicate that FuSTAR has a good load following capability because of the negative temperature reactivity feedback and the existence of control system, which fully meets the requirements of safety operation of the reactor.

BackgroundIn pressurized water reactors (PWR), grid to rod fretting (GTRF) is a primary cause of fuel failure due to fuel rod vibrations. Understanding and characterizing the dynamics of fuel rods is essential for analyzing GTRF and ensuring reactor safety.PurposeThis study aims to develop a vibration analysis method that can reasonably represent the dynamics of fuel rods within a reactor, focusing on the vibration characteristics of fuel rods supported by multiple positioning grids.MethodsFirstly, a mechanical model was established for a multi-span elastically supported fuel rod restrained by multiple sets of positioning grids. The restraint effect of the grids was simplified into tension and compression springs and torsion springs within the elastic range. Then, a displacement function based on an improved Fourier series was constructed for the whole beam section, and the modal state was solved using the energy principal method. Subsequently, the Improved Fourier Series Method (IFSM) was used to address boundary discontinuity issues, eliminating the need to reconstruct the model for structural and boundary changes. Finally, the accuracy of this method was verified by comparing with the finite element calculation results, and the vibration characteristics of fuel rods were analyzed.ResultsThe results show that the tension spring stiffness is the dominant factor influencing the overall variation pattern of the intrinsic vibration frequency of the fuel rod. The influence of the torsion spring on the vibration characteristics is dependent on the tension spring stiffness, with minimal impact when the tension spring stiffness is small. Changes in boundary conditions affect the system's stiffness, which in turn influences modal frequency. Increased overall stiffness leads to increased deformation resistance and higher modal frequency.ConclusionsThe study concludes that the strength of the restraint effect of the spacer grid on the fuel rod significantly influences the vibration characteristics of the fuel rod under multi-span elastic support. The developed method provides a reliable tool for analyzing the vibration characteristics of fuel rods with multiple grid constraints, which can be used as a reference in practical engineering applications.

BackgroundThe fluids on both sides of the helical coil steam generator of the high-temperature gas-cooled reactor (HTGR) are helium and water respectively, whose physical properties are quite different and the transient response time is different. Traditional semi-implicit finite difference scheme applied to thermal hydraulic analysis code can only apply small time steps due to Courant-Friedrichs-Lewy (CFL) condition, which will decrease the computation efficiency.PurposeThis study aims to develop and verify a new transient analysis code using all-implicit algorithm for the helical coil steam generator of the high-temperature gas-cooled reactor.MethodsFirstly, based on homogeneous flow model, a fully implicit finite difference scheme for the convection and diffusion term combined with the full coupling solution algorithm of flow and heat for thermal conductivity process to develop a new transient analysis program, named NUSOL-HTGRSG, for the helical coil steam generators of HTGR. Then, verification of the code was conducted in the four aspects: the design condition of the HTR-PM steam generator used for steady-state calculation validation, the number of grids changed for spatial sensitivity analysis, the time step changed for time sensitivity analysis, and the transient calculation carried out under the same disturbance (the flow rate of the primary side of the steam generator reduced by 10%). and results were compared with that of NUSOL-SG calculation.ResultsSteady-state validation results show that the relative errors of outlet temperatures and pressure drops in the primary and secondary sides are generally within 1%. Transient validation results indicate that, under identical transient conditions, the maximum relative deviation between the transient responses of the two codes is 1.4%.ConclusionsThe validation results demonstrate that the NUSOL-HTGRSG code can effectively predict the operating parameters of the helical coil steam generator in HTGRs under steady-state conditions and accurately capture its transient characteristics with a relatively large time step (5 s).

BackgroundMegawatt-level nuclear reactor combined with helium-xenon Brayton cycle system can effectively meet the energy needs of large-scale deep space explorers, satellite base, deep-sea unmanned underwater vehicle and other special energy power equipment for high power, small size, highly reliable power supply, which has wide application foreground and research necessity. Currently, the study of the physical properties of helium-xenon gas mixtures in non-ideal state is not sufficient.PurposeThis study aims to establish the thermophysical property model and the thermodynamic model of helium-xenon Brayton cycle, and analyze the effect of the non-ideal gas characteristics to the thermal performance of the cycle.MethodsThe second or third order virial expansion was adopted to construct the helium-xenon mixture physical property model to reflect the deviation caused by the non-ideal gas characteristics. The thermodynamic models of turbine, compressor, mixing chamber, and heat exchanger were conducted on the basis of thermophysical property model. Then, the function models of efficiency and specific work were derived from the thermodynamic models of the above main components, and verified by the submerged subcritical safe space reactor (S4) design. Finally, the influence of the thermophysical properties of helium-xenon mixture on thermal performance of helium-xenon Brayton cycle system such as adiabatic coefficient, pressure loss and relative convective heat transfer coefficient at different temperature, pressure and molar fraction of helium was analyzed, and the influence of He-Xe mixing ratio on the He-Xe thermophysical property under different temperature and pressure was explored.ResultsThe second or third order virial expansion was adopted to construct the helium-xenon mixture physical property model to reflect the deviation caused by the non-ideal gas characteristics. The thermodynamic models of turbine, compressor, mixing chamber, and heat exchanger were conducted on the basis of thermophysical property model. Then, the function models of efficiency and specific work were derived from the thermodynamic models of the above main components, and verified by the submerged subcritical safe space reactor (S4) design. Finally, the influence of the thermophysical properties of helium-xenon mixture on thermal performance of helium-xenon Brayton cycle system such as adiabatic coefficient, pressure loss and relative convective heat transfer coefficient at different temperature, pressure and molar fraction of helium was analyzed, and the influence of He-Xe mixing ratio on the He-Xe thermophysical property under different temperature and pressure was explored.ConclusionsThe proposed model can accurately calculate the thermophysical properties of the He-Xe mixture, including density, specific heat capacity, viscosity, thermal conductivity and Prandtl number can be accurately calculated by the proposed model under different helium molar fraction. The model proposed in this work can be applied to the design and optimization of the He-Xe Brayton cycle systems and direct the device selection of the He-Xe Brayton cycle system.

BackgroundThe Electron Cyclotron Resonance (ECR) preionization is important for the reliable start-up of spherical tokamaks.PurposeThis study aims to investigate the effects of power deposition, electron density, and electron temperature of ECR pre-ionization process under different power conditions by simulation.MethodThe spherical tokamak device NCST (NanChang Spherical Tokamak) at Nanchang University was selected as research object, and COMSOL Multh-physics, a multi-physics simulation software, was utilized on the basis of the finite element method to simulate the process of ECR pre-ionization forming plasma in the device. Firstly, a three-dimensional model of the NCST device was established by using the parametric modeling method. Then, through the AC/DC, radio frequency (RF) and plasma modules in COMSOL software, and by correctly defining the electromagnetic wave source term, plasma parameters and reasonably setting boundary conditions, the laws of magnetic field, electron density and electron energy changing with time and space were solved through multi-physics field coupling.Results & ConclusionThe results show that increasing the input power can greatly shorten the ionization time of electrons, and greatly increase the peak electron density and electron temperature of plasma. However, too high input power will also cause too large plasma density generated by ionization, making the incident electromagnetic wave difficult to reach the resonance region, thus reducing the heating efficiency of ECR. Higher power can make the heating effect of ECR better, hence greatly shorten the ionization time of electrons, but the duration of this process will also decrease with the increase of power.

BackgroundThe thermal stratification in the upper plenum of lead-bismuth fast reactor after emergency shutdown has a significant impact on the structural integrity of the reactor and the residual heat removal capacity of the natural circulation. The research on thermal stratification based on Computational Fluid Dynamics (CFD) method has the problems of large computational overhead and time-consuming whilst the existing standard dynamic mode decomposition (DMD) method has poor forecasting results on thermal stratification.PurposeThis study aims to solve this problem by proposing a thermal stratification model reduction method for the upper plenum of lead-bismuth fast reactor.MethodsFirstly, the high-precision full-order snapshot was obtained on the basis of the CFD program FLUENT. Then, based on the truncated DMD, the time step samples were compressed according to the characteristic frequency, and the thermal stratification reduction model was constructed by combining the Long Short-Term Memory (LSTM) neural network with DMD. Finally, three methods, i.e., standard DMD, improved DMD and improved DMD-LSTM, were comparatively analyzed in terms of temperature oscillation error and computation time.ResultsComputational results show that the thermal stratification model reduction method based on improved DMD and LSTM in the upper plenum of the lead-bismuth fast reactor achieves best performance, with root mean square error reduced by 46.60% and 30.45% respectively, compared to standard DMD and improved DMD. The computational time of the improved DMD and LSTM is only 4.4% of FLUENT's, significantly improving efficiency and enabling faster emergency response in lead-bismuth reactors.ConclusionsResults of this study verify that the thermal stratification model reduction method proposed in this paper can better simulate the temperature distribution in the upper plenum and realize the rapid prediction of the thermal stratification phenomenon.

BackgroundThe control rod channel tubes of the Thorium Molten Salt Reactor (TMSR) are typical high-temperature, thin-walled, long cylindrical shells designed to withstand external pressure, with creep buckling as its primary failure mode.PurposeThis study aims to use numerical simulation methods to study the creep buckling instability behavior of control rod channel tubes at the elevated temperatures.MethodsFirstly, the Norton creep model and material parameters for the UNS N10003 alloy was obtained on the basis of the high-temperature creep test data. Furthermore, finite element analysis software ABAQUS was employed to assess eigenvalue buckling and creep buckling for TMSR control rod channel tubes. Sensitivity analysis was conducted on the key factors causing buckling instability, and an empirical formula for creep buckling life was obtained.ResultsThe analysis results reveal that temperature, pressure, and structural dimensions significantly influence the tube's creep buckling life, and the derived empirical formulas can be used to verify the durability of the tubes. To ensure a design life of 30 a for the casing at 700 ℃, the tube height needs to be controlled below 3 m. If the design life is 10 a, the tube height can be increased to 6 m.ConclusionsThis study offers engineering guidance for the stability design of TMSR control rod channel tubes and high-temperature structures under complex conditions, and it also serves as a basis for predicting the creep buckling lifespan of other high-temperature thin-walled structures.

BackgroundMolten salt reactor is a promising type of reactor in the fourth generation advanced nuclear reactor system due to its excellent safety and economy. However, as the coolant for the molten salt reactor system, lithium fluoride beryllium (FLiBe) has a melting point of 460 ℃, which is much higher than the ambient temperature, so there is a risk of coolant solidification in the system.PurposeThis study aims to establish a one-dimensional solidification model with mushy zone effect based on energy conservation and enthalpy porous medium model.MethodsFirstly, based on the energy conservation equation, a solidification layer thickness model was established and a source term model with mushy zone was established based on the enthalpy porous medium model. The velocity and temperature distribution models were obtained on the basis of the boundary layer theory. Secondly, the molten salt solidification experiment was designed to verify these models. Finally, the system safety analysis program ASYST-SF was employed to simulate the filling behavior of FLiBe coolant in the pipe.ResultsThe experimental verification results show that the overall model error is less than ±10%, meeting the requirements of reactor system safety analysis. The evolution behavior of fluid temperature, solidification layer thickness, and pressure drop of the pipe filling behavior under typical working conditions are observed.ConclusionsThe model and calculation results are of great significance for improving the operational safety of molten salt reactors.

BackgroundCorrosion products such as iron and nickel ions generated in the steam generator (SG) of a pressurized water reactor (PWR) deposit on the fuel rods in the reactor core, forming Chalk River Unidentified Deposits (CRUD). Activated by neutron irradiation in the reactor core, part of the CRUD layer transforms into radioactive substances, which are mainly 58Co and 60Co. Then the radioactive 58Co and 60Co are carried by the coolant into the entire primary loop. The existing research lacks a comprehensive modeling and discussion on the distribution of radioactive materials 58Co and 60Co in the primary loop. Predicting the content and distribution of radioactive materials 58Co and 60Co in the primary loop and assessing the impact of water chemistry and thermal parameters are of significant importance for radiation protection and core parameter design.PurposeThis study aims to explore the production and distribution of radioactive materials in the primary loop due to the deposition of CRUD in reactor core, with a typical PWR primary loop as the research subject.MethodsFirstly, a predictive model for CRUD deposition and radioactive materials production distribution was established that encompassed CRUD deposition and radioactive material prediction. Then, the primary loop of PWR was simplified into five key nodes, i.e., the core, soluble corrosion products, SG, corrosion particulates, and erosion particles, to address the generation, migration, deposition, and growth of CRUD based on the principles of mass transfer and water chemistry. The proportion of particles returning coolant was controlled by the purification efficiency in the erosion particle node. Finally, the activation of CRUD and the migration, deposition, and erosion of radioactive materials at each node were correspondingly considered on the basis of the activation theory, and the distribution of radioactive materials in the primary loop was obtained by establishing and solving the mass transport balance equations for each node. Based on this established model, a comprehensive analysis was conducted on the influence of coolant flow rate, hydrogen content, and coolant inlet temperature.ResultsThe calculation results indicate that the radioactive materials inventory increases with an increase in coolant flow rate and hydrogen content. The impact of coolant flow rate and hydrogen content on the radioactive materials inventory of steam generators (SG) is 93.9% and 10% greater than the core. As the coolant inlet temperature increases by 8%, the radioactive materials inventory decreases by 9%, and its impact on the core is 19% greater than the SG. The model predictions for CRUD deposition and radioactive materials distribution closely align with the results obtained from the code CRUDSIM (Chalk River Unidentified Deposits SIMulation) with a difference less than 5%.ConclusionsThe results of this study demonstrate a significant influence of coolant flow rate, hydrogen content, and inlet temperature on the radioactive material content and distribution in the primary loop. Moderating coolant flow rates and reducing hydrogen concentrations are beneficial for lowering the content of 58Co and 60Co in SG. Conversely, increasing coolant inlet temperature effectively reduces the content of 58Co and 60Co in the core.

BackgroundThe inner working conditions of a reactor are complicated and affected by many factors. Accurate prediction of the key thermal parameters of the reactor core under various working conditions can greatly improve reactor safety. Most of the existing research focuses on the prediction method that uses a single neural network. In the case of excessive noise, a single neural network cannot sufficiently eliminate noise and accurately detect data change.PurposeThis study aims to propose a novel transient thermal hydraulic parameter prediction method for fast reactor core, making use of a model that is based on the empirical mode decomposition (EMD) and singular spectrum analysis (SSA) combined with an adaptive radial basis function (RBF) neural network.MethodsFirstly, the 1/2 China Experimental Fast Reactor (CEFR) was used as the research object, and the fast reactor subchannel program SUBCHANFLOW was employed to generate a time series of transient core thermal hydraulic parameters. Then, two combined models, i.e., EMD-RBF and EMD-SSA-RBF, were used to predict the core mass flow rate and time series of the maximum temperature on the surface of the cladding. Both the single step prediction and continuous prediction were performed.ResultsThe results show that compared with a single RBF neural network, the single-step prediction errors of mass flow rate with the EMD-RBF combined neural network and EMD-SSA-RBF combined neural network are reduced by 41.2% and 86.7% respectively, whilst the single-step prediction errors of temperature are reduced by 44.7% and 60.5% respectively. Not only the prediction errors are significantly reduced, but also the calculation time for parameter prediction is shortened.ConclusionsThe combined neural network models proposed in this study can make fast and high-precision predictions, providing advantages over the deep neural network. Hence have certain reference value for improving the safety of the reactor in engineering applications.

BackgroundThere is a large pressure difference and temperature difference on both sides of the heat transfer tube of the lead-bismuth reactor steam generator, and the lead-bismuth coolant has a corrosive effect on the heat transfer tube, there is a possibility of rupture in long-term operation.PurposeThis study aims to reveal the mechanism of pressure pulse generation in the steam generator tube rupture (SGTR) of lead-bismuth reactor, obtain the dynamic distribution of lead-bismuth, water and vapor components, and the pressure and temperature fields.MethodsFirstly, based on the Computational Fluid Dynamics (CFD) method, a numerical simulation was carried out on the process of high-pressure water jet injection into a high-temperature lead-bismuth molten pool by coupling the Volume of Fluid (VOF) model, the Realizable k-ε model, and the Lee phase change model. Then, high pressure water jet injection of liquid lead bismuth experiment was conducted on the basis of LIFUS 5 platform to verify simulation results.ResultsThe results show that the simulated pressure and temperature changes are in good agreement with the experimental results, the main reason for the increase in pressure after high-pressure water injection is the large amount of vapor generated by depressurization and heating evaporation. The pressure peak detected at the position of x/d=1 on the axial centerline is the highest, which is 0.2 MPa, the farther away from the injection port, the smaller the detected pressure peak is, at x/d=20, no obvious pressure peak can be detected. During the vapor migration process, a K-H unstable vortex appeares at the interface between lead-bismuth and vapor, and the wake entrained and entrained part of the lead-bismuth, causing the vapor pockets to fragment into multiple vapor blocks.ConclusionsThe model proposed in this study has high reliability, and the research results can provide technical support for the safety design of lead-bismuth reactors.

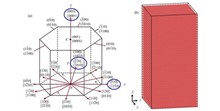

BackgroundPebble Bed High Temperature Gas-cooled Reactor (PB-HTGR) is very different from other type of reactor in terms of its geometric structure, neutron characteristics, and mode of operation. Thus, it is imperative to develop a specialized analysis and calculation code for the PB-HTGR. A neutronics calculation module of the neutronics and thermal hydraulic calculation program suitable for PB-HTGR, named as NECP-Panda, has been independently developed by the Nuclear Engineering Computational Physics (NECP) Laboratory of Xi'an Jiaotong University.PurposeThis study aims to explore how the neutronics calculation module in NECP-Panda is achieved to improve the precision of core physics calculation of the PB-HTGR.MethodIn the neutronics calculation, NECP-Panda adopted the two-step method. The first step was based on Monte Carlo method to calculate the component homogenized group constants while the homogenization of the pebble bed was performed using collision probability equations in the second step, and the whole-core diffusion calculation was subsequently completed using the three-dimensional cylindrical geometric Nodal Expansion Method (NEM). In order to accurately account for the influence of neutron leakage effect on the group constants of the model region, the diffusion calculation and neutron leakage correction were iterated until the group constants of the region converged. In addition, the neutron streaming effect of the porous structures was corrected in the iteration, and the cavity at the top of pebble bed was treated specially in the diffusion calculation. Finally, the NECP-Panda was verified by both the simplified mixed pebble bed reactor and the High Temperature Reactor Pebble-bed Module (HTR-PM).ResultsThe numerical results show that the eigenvalue calculation of the simplified mixed pebble bed reactor, calculated by NECP-Panda, is close to the Monte Carlo continuous energy result. The calculated HTR-PM critical loading height of the HTR-PM is highly consistent with the results of Monte Carlo continuous energy calculation, and the absorber value is also in good agreement.ConclusionsVerification results in this study demonstrate that NECP-Panda possesses exceptional computational power and accuracy for the neutronics calculation of the PB-HTGR, establishing a solid foundation for the development of subsequent modules.

BackgroundThe mixing vane plays an important role in reducing the hot-spot factor of the core, and the current studies are mostly aimed at analyzing the heat transfer performance, flow characteristics, and mixing performance under different mixing wing types and deflection angles. There are fewer studies on the correlation and quantitative effects of the fine structure of the mixing wing on the flow field.PurposeThis study aims to gain a deeper understanding of the impact of mixing vane structure characteristics on the thermal hydraulic performance of the reactor core, and analyze the correlation between mixing vane structure and flow fields.MethodsFirstly, the parameterized and automated construction of the split vane structure was realized through the geometric automated configuration and calculation technology based on computational fluid dynamics (CFD) calculations. Secondly, through the orthogonal design of the split vane structure parameters and the analysis of the simulation results, the influence of the split vane structure on the thermal parameters such as the flow field pressure drop and cross-flow velocity was clarified. Simultaneously, the ANOVA (Analysis of Variance) method was used to compare the importance of different stirred wing parameters. Finally, the optimal mixing vane structure was obtained by direct analysis and its flow field characteristics were calculated. The flow field downstream of the churning wing was further calculated and analyzed.ResultsUnder the geometric structure of split mixing vane adopted in this article, the maximum difference in outlet pressure of different churning wings is 1.1 kPa, which is 41% of the average pressure drop in the whole computational fluid domain, and the maximum difference in cross-flow velocity under different churning wings is 1.1 m·s-1, with the maximum cross-flow velocity being 173% of the average cross-flow velocity. The angle of the mixing vane is strongly correlated with the flow field that has the greatest impact on the mixing effect, followed by the shape and length of the mixing vane. The setting of the thermal boundary conditions has less influence on the flow field results with the optimal design of churning wing.ConclusionsThe method proposed in this provides a design basis for subsequent research and engineering application of the mixing wing structures.

BackgroundMixing vanes can enhance the critical heat flux of fuel assemblies by generating vortices. Current studies primarily focus on the optimized design of traditional mixing vanes made of zirconium alloy and does not take into account the impact of mixing vanes on fretting wear of fuel rods.PurposeThis study aims to propose a novel type of mixing vane made of shape memory alloys to address the micro motion abrasion problem of fuel rods.MethodsThe two-way fluid-structure-thermal coupling analysis was employed to simulate the flow field distribution, pressure drop loss and fuel rod stress under a new type of mixing vane. Then, a nonlinear vibration model of fuel rod force with mixing vane made of shape memory alloys was established. Finally, a comparative analysis was conducted on the impact of different mixing vanes on the fretting wear power between fuel rods and the spacer grids.ResultsThe results indicate that shape memory alloys mixing vanes experience a similar pressure loss compared to traditional mixing vanes; the enhanced heat transfer effect increases with the maximum bending angle of the mixing vanes. Simultaneously, the fretting wear power between fuel rods and the spacer grids increases with the bending angle of the mixing vanes.ConclusionsShape memory alloys mixing vanes do not generate additional pressure loss while strengthening heat transfer between fuel rods and coolant.

BackgroundHeat pipes, as highly efficient heat transfer components that combine evaporation and condensation, are widely used in fields such as nuclear energy and aerospace. If geyser boiling occurs in a heat pipe, it will cause temperature fluctuations, thereby affecting the safety of the entire heat pipe stack.PurposeThis study aims to analyze the heat transfer characteristics of geyser boiling in high-temperature sodium heat pipes.MethodsFirstly, an experimental platform for high-temperature sodium heat pipe heating was established. Then, the heat transfer characteristics of the evaporation section of a heat pipe using liquid metal sodium as the working fluid were studied at different liquid level depths and various mesh sizes, and the temperature and pressure parameters of the sodium heat pipes under different power conditions were obtained. Subsequently, the variation pattern of the geyser boiling oscillation period with changes in heating power and the trends in the heat transfer coefficient of the evaporation section with variations in liquid pool depth and mesh count were summarized. Finally, based on the experimental data, a model for the heat transfer coefficient of the evaporation section of sodium heat pipe in single-phase convection and geyser boiling regions was proposed.ResultsExperimental results show that the temperature oscillation period is shortened with the increase of heating power. At the end of the heat pipe startup phase, the oscillation amplitude significantly decreases. The new evaporation section heat transfer model shows a maximum error of 21% in the single-phase convection zone and a maximum error of 39% in the intermittent boiling zone.ConclusionsThe results indicate that, within a certain range, the higher the filling ratio and the higher the mesh count of the wire mesh, the better the heat transfer performance of the heat pipe. Additionally, when the heat pipe experiences geyser boiling, its heat transfer performance is significantly lower than that during normal operation.

BackgroundAfter a steam generator tube rupture (SGTR) accident occurs in a lead-bismuth eutectic (LBE) alloy-cooled reactor, supercooled water on the secondary side is injected into the high-temperature molten LBE on the primary side. Possible consequences arising from SGTR include LBE solidification, damage to the reactor components caused by pressure waves, and unexpected reactivity owing to steam migration into the reactor core.PurposeThis study aims to conduct a computational fluid dynamics pre-computation for the LBE alloy-cooled reactor to clarify the phenomena and determine the working conditions of LBE-water interaction.MethodsFirstly, a large experimental platform for the LBE-water interaction was set up by the Innovative Nuclear System Laboratory in Shanghai Jiao Tong University. Then, the physical process of of LBE-water interaction was described on the basis of Fluent, coupling VOF model, Lee model, and SST k-ω model, and the numerical methodology with existing experimental data was validated. Thereafter a two-dimensional model of the experimental facility was established using ANSYS Fluent. Finally, multi-case simulations were conducted to simulate the overall process of the experiment and examine the effects of water inlet velocity, water inlet temperature, and initial LBE temperature.ResultsThe simulation results indicate that the jetting process can be divided into three stages and LBE solidification is avoided under the designed conditions. The minimum LBE temperature decreases with lower water inlet temperatures or higher inlet velocities. Concurrently, the maximum void penetration depth increases with elevated water inlet temperatures and velocities.ConclusionsThe results of this study provide a valuable reference for future experimental studies.

BackgroundThe operational characteristics of passive residual heat removal systems (PRS) under marine conditions are crucial for the thermal and hydraulic safety of offshore floating nuclear power plants.PurposeThis study aims to verify the applicability of the re-developed RELAP5 code under inclined conditions.MethodsBased on the small-scaled secondary side of the PRS experimental device, simulation of the experiments were carried out by using the secondary-developed RELAP5 code under the operating conditions of the inclination angle from -24° to +24°. Then, a comparative analysis of experimental data was performed to verify the applicability of this secondary-developed code.ResultsThe results show that the length of the condensing section in the C-type heat exchanger is changed under inclination conditions, and the larger the tilt angle, the better the overall heat transfer effect is achieved. Besides, the re-developed RELAP5 code can effectively predict changes in the system operating characteristics under tilt conditions, and the deviation between the calculated results and the experimental values is within ±4%.ConclusionsThe results of this study provides some reference for the design of the secondary side passive heat removal system under marine conditions.

BackgroundThermal conductivity of SiC composite cladding significantly decreases after irradiation, leading to cladding failure due to high tensile stress under pellet-cladding mechanical interaction (PCMI).PurposeThis study aims to address the challenges of high fuel temperature resulting from low thermal conductivity and cladding failure under PCMI in SiC cladding fuel rods.MethodsFirstly, a design of pellet-cladding gap filled with liquid LBE (Lead-Bismuth Eutectic) duplex SiC cladding fuel rod was proposed, and the gap filling material model was developed based on FRAPCON code. Then, the model was applied to incorporating the influence of LBE filling on gap heat transfer, accounting for changes in immersion height due to variations in gap and LBE volume during operation, and evaluating the impact of LBE volume on gas space and internal pressure within the fuel rod. Subsequently, the performance of this UO2-SiC cladding fuel rod with LBE filled gap preliminarily analyzed under normal operating conditions with different initial LBE filling heights, using a typical pressurized water reactor fuel rod power history. The effects of different initial filling heights on reducing fuel temperature during operation and their impact on internal pressure were investigated. For high burnup fuel rods, further optimization of parameters including initial internal pressure, plenum length, and gap size was carried out based on the characteristics of the LBE gap and SiC cladding, resulting in an enhanced performance of UO2-LBE-SiC fuel rod. Finally, fuel performance of three designs of fuel rods (UO2-SiC, UO2-SiC with central void, UO2-LBE-SiC) were compared.ResultsUnder the condition of high power and high burnup, the decrease of the gap size and the void volume results in a significant increase in internal pressure. Increasing plenum length can compensate for the gas volume occupied by LBE and maintain the fuel rod internal pressure lower than the original He gap. SiC cladding can withstand large compressive stress and gap heat transfer no longer depends on He, hence the initial internal pressure of fuel rods is optimized to reduce internal pressure during operation. The final optimized design parameters for UO2-LBE-SiC include a 70% fuel stack height as the initial LBE filling height, atmospheric pressure for the initial gas, a 50% increase in plenum length, and an initial gap size raised to 99 μm. The peak fuel temperature is 1 972 K, with a peak fission gas release of approximately 20% and a peak internal pressure of about 25 MPa. The hoop stress in the Ceramic Matrix Composite (CMC) layer consistently remains below its ultimate tensile strength, and the chemical vapor deposition (CVD) layer is predominantly under compression, with a maximum tensile stress of 5 MPa. The failure probability is less than 10-6, meeting safety criteria.ConclusionsThe results of this study show that the design of UO2-SiC with pellet central void cannot avoid cladding failure. Due to the excellent thermal conductivity of the LBE gap, the pellet-cladding temperature difference is minimal, increasing the gap size can weaken PCMI and reduce the probability of fuel failure without affecting the temperature field distribution.

BackgroundSolving benchmark problems is a significant step in the validation of numerical simulation programs. The Experimental Breeder Reactor II (EBR-II) is a famous benchmark for sodium-cooled fast reactors (SFR), with a complicated core configuration and spatial distribution of nuclide density, hence the modeling difficulty and computational cost of its fine numerical models are relatively high. Therefore, simplified model that mixing the spatial distribution of nuclide density by the component type is adopted in many studies on EBR-II benchmark calculation.PurposeThis study aims to contrast the difference between the results of the fine model and the simplified model, evaluating the rationality of the simplification.MethodsIn this study, both the fine model and the simplified one were built using LoongSARAX, a neutronic numerical program for fast reactors developed by Xi'an Jiao Tong University. Some approximations were applied to these two models, i.e., one-dimensional homogenization adopted for the half-worth driver assembly to handle its complex radial geometry and the super-assembly method adopted in the cross-section generation of poison elements. Finally, deviation between neutron physical properties in two models was evaluated in terms of computation time consumption, effective multiplication factor, neutron flux density distribution.ResultsThe evaluation results show that the spatial distribution of fuel nuclide density presents strong asymmetry and strong non-uniformity in the simplified model, and calculation time spent in the simplified model is one-tenth of that in the fine model. Compared with the fine model, the effective multiplication factor (keff) is 1.383×10-2 lower than in the fine model and the spatial distribution of neutron flux is lower in the center and higher in the outer core whereas the maximum relative deviation between neutron flux in two models is 4.25%.ConclusionsThis study demonstrates that the simplified model has a much lower calculation cost but limited numerical accuracy in keff and neutron flux, hence it is still necessary to adopt the fine model when necessary.

BackgroundReactor activation-burnup calculation is a crucial component of reactor analysis, involving an iterative process that combines criticality programs with point burnup programs.PurposeThis study aims to design and develop a novel lightweight, general-purpose activation-burnup program, named LightAB (Light Activation and Burnup) for activation-burnup calculation.MethodsBurnup databases on the basis of ORIGEN-2 and ORIGEN-S were utilized and the Chebyshev rational approximation (CRAM) algorithm was implemented in LightAB for accurate burnup systems. Point burnup calculations in decay mode, constant flux mode, and constant power mode were supported by LightAB with well-structured program architecture, consisting of a solver module, an I/O module, and a burnup chain module. In the meanwhile, nuclide was used as the fundamental unit of storage, and physical quantities such as burnup database path and sub-burnup step division were specified as the input module of LightAB. Thereafter, the decay of 237Np and the irradiation of Zr under fixed-flux conditions were calculated using LightAB for accuracy validation, and various reactor burnup models, including pressurized water reactor (PWR) cell, PWR assembly, and Organisation for Economic Co-operation and Development/Nuclear Energy Agency (OECD/NEA) fast reactor models, were calculated by coupling LightAB with RMC programs. Finally, LightAB was applied to the irradiation production of transplutonium isotope with comparison to RMC.ResultsResults of LightAB are consistent with that of ORIGEN 2.1 for the calculation of 237Np's decay and Zr's irradiation. Calculation results of LightAB coupling with RMS programs are consistent with RMC calculations. The errors between LightAB and RMC for production calculation of transplutonium isotope in three cases are within 5%.ConclusionsLightAB has shown promising application prospects in the irradiation production of transplutonium isotopes compared with RMC simulation calculations.

BackgroundThe helical-coiled once-through steam generator (H-OTSG) has the advantages of compact structure and strong heat transfer ability, which is appropriate for lead-cooled fast reactor (LFR). The two-phase flow instability may cause mechanical vibration and thermal fatigue of heat transfer tube bundles, posing a serious threat to the safe operation of steam generators.PurposeThis study aims to explore the oscillation modes and influencing laws of two-phase flow instability of H-OTSG, providing reference for industrial design.MethodsFirstly, RELAP5/MOD3.4 code was applied to modelling the helical-coiled once-through steam generator with 14 parallel heat exchange tubes. The primary working fluid of H-OTSG was liquid lead bismuth eutectic (LBE) and the secondary fluid was water. Then, the oscillation behavior during start-up was studied based on time-domain method and the oscillation characteristics and the parameter sensitivity of the stable boundary were analyzed. The limit cycles of the oscillation in each channel were shown on the pressure-drop vs. flow-rate plane. Finally, the influence of structural parameters on system stability were explored, so did that of operating parameters such as the pressure, flow rate, and temperature of the secondary fluid.ResultsThe results indicate that the operating parameters exhibit density wave oscillations at the heating section in a (n-2,2) pattern, with superimposed flow pattern transition instability. The smaller the flow amplitude, the shorter and thinner the corresponding limit cycle, and the closer to the circle. In the same channel, as the driving force increases, the flow amplitude gradually decreases, and the limit cycle also gradually shrinks. In addition, as the inlet throttling has been increased from 1 100 to 1 700, the duration of oscillation shortened from approximately 6 000 s to less than 1 000 s, and the amplitude decreased by nearly 30%. With the increase of the outlet throttling from 0 to 200, the duration of oscillation has been lengthened from less than 5 400 s to approximately 18 000 s. In addition, the steam temperature and the power-flow ratio of the channel increase with the increase of outlet throttling, resulting in reduced system stability. As the system pressure is increased from 3.7 MPa to 4.4 MPa, the oscillation duration of the flow curve shortens from 10 000 s to less than 5 000 s, and the amplitude also decreases. The density difference between the liquid phase and vapor phase decrease with the increase of system pressure. As a result, two-phase frictional resistance is decreased, the self-sustained oscillation of mass flow is suppressed, and the system stability is increased.ConclusionsResults of this study demonstrate that the system stability of the helical-coiled once-through steam generator can be improved by increasing inlet throttling and system pressure and reducing outlet throttling, and involved structural and operational parameters should be focused on during the design process.

BackgroundThe operation of marine reactors and floating nuclear power plants is challenged by the thermal fluctuation of heat transfer surfaces caused by oceanic motion. The pyroelectric effect of lithium tantalate (LiTaO3, LT), a material with high Curie temperature and low relative dielectric constant that changes its spontaneous polarization with temperature variations, has the potential to influence the wettability of surfaces, thereby improving heat transfer performance.PurposeThis study aims to prepare LT coatings with controlled pyroelectric properties and to investigate the mechanism of temperature-dependent wettability of LT, thereby enhancing heat transfer efficiency in two-phase systems.MethodsFirst of all, the sol-gel method was used to achieve the controlled synthesis of LT. Subsequently, scanning electron microscopy (SEM) was employed to characterize micro surface morphology of coatings whilst the crystal phases and crystallinity in LT coatings were analyzed by X-ray diffraction (XRD) patterns. Then, the effects of synthesis parameters on the crystallinity, coating quality, particle size and pyroelectric properties of LT coatings were explored by systematically changing the curing time, sol settling time and annealing temperature in the sol-gel method. Finally, the pyroelectric effect and mechanism of wettability modulation were investigated by evaluating the hydroxyl radicals generated during temperature changes.ResultsThe results indicate that the particle size of LT increases with increasing annealing temperature. The pyroelectric characteristics are significantly influenced by the thickness and particle size of the coatings, pyroelectric performance is enhanced by increasing the coating thickness and decreasing the particle size. Fluorescence spectroscopy analysis shows that the hydroxyl radical concentration of LT increases during the heating process, confirming that LT has the ability to regulate the hydroxyl radical concentration when undergoing heating and cooling cycles.ConclusionsResults of this study demonstrate that LT coatings have temperature-dependent surface wettability of heat transfer in two-phase system with variable temperature.

BackgroundThe neutral beam injection system (NBI) has the highest heating efficiency and the clearest physical mechanism, so it has become one of the main auxiliary heating methods used in the world's large magnetic confinement controlled thermonuclear fusion devices. The application of NBI system based on negative ion source is increasingly demanding and urgent. Cavity ring-down spectroscopy (CRDS) is a highly sensitive absorption spectrum measurement technique with relatively simple principle, and the measurement results are not limited by electromagnetic field interference and other plasma parameters.PurposeThis study aims to explore the characteristics of negative ion generation in negative ion source based on CRDS, and measure negative ion density produced by NBI.MethodsFirst of all, a CRDS diagnostic system was developed on a large area negative ion source. Then the related characteristics of negative ion production was investigated by sequentially measuring the decay time of pulsed laser in front of the plasma electrode plate under different experimental parameters. Finally, developed CRDS diagnostic system was employed to study the characteristics of hydrogen anion generation under different experimental parameters, such as radio-frequency (RF) power, source pressure and bias voltage.ResultsExperimental results show that produced negative hydrogen ions increase with the increase of RF power and pressure in the source cavity. Due to the different effects of the two changes on the electron temperature, the growth rate of negative hydrogen ions changes opposite under the influence of different power and pressure. There is an optimal value of bias voltage that is conducive to the generation of negative hydrogen ions because of the plasma potential.ConclusionsApplication of CRDS-based measurement approach in this study provides valuable experience for further research on the generation of negative hydrogen ions and the beam quality.

BackgroundGas-cooled fast reactor (GFR) is one of the six recommended nuclear reactor types of Generation IV Forum (GIF) with the lowest technical maturity. Cooled by inert gas like helium and super critical carbon dioxide which performs not so good as water or liquid metal in heat transfer, GFR has been challenged by safety issues especially in Loss-Of-Coolant-Accident (LOCA) events. It has been considered to be an effective way to improve the core inherent safety of GFR by strengthening the temperature feedback on reactivity in the core. However, with no moderating materials and low neutron reaction rates which cause a harder neutron spectrum than other reactor types, GFR has very weak negative temperature feedback.PurposeThis study aims to optimize nuclear design of GFR core by increasing the negative temperature feedback.MethodsFirstly, moderating materials were utilized in the fuel assemblies (FAs) in order to get a softer neutron spectrum in the core and increase both the doppler effect of the fuel and the temperature feedback on reactivity. Four moderators including graphite, beryllium oxide, zirconium carbide and zirconium hydride were used in the FA with different geometric structures such as uniformly mixing in the fuel pellets, separate rods distributed in the fuel rod bundles and thick layer outside the fuel rod bundles. Then, Monte Carlo (MC) calculation software RMC was employed to carry out neutronics analysis of the GFR core. Neutronics characteristics of these FA models was comparatively analyzed in details to find the best performance FA model. Finally, a 10-megawatt-power micro GFR core design was given based on the selected FA structure. Effects of the High-to-Diameter ratio (H/D) value as well as the uranium enrichment of fuel on the temperature feedback of the core were thoroughly studied and optimization of the GFR nuclear design was conducted.ResultsThe MC simulation results show that the optimized GFR core has a more than twice larger reactivity temperature coefficient value compared to the general core design, which greatly enhances the inherent safety of GFR core. Meanwhile, flat power distribution of the core has been demonstrated with the axial and radial power peaking factor of 1.14 and 1.23, respectively. Results of temperature field around the hottest fuel rod show sufficient safety margin of and that the core has the ability to automatically shutdown by negative temperature feedback solely.ConclusionsFA model with a layer of beryllium oxide moderator has shown the best performance, and the effectiveness of the optimization methods for reactivity temperature feedback and core design of GFR is verified in this study, providing design experience for the future GFR nuclear design and optimization.

BackgroundWith the development of nuclear-thermal coupling technology, it is essential to consider the strong coupling effects between multiple physics fields and achieve high precision and large-scale parallel computing. Simultaneous solutions to the conservation equations of multiple physics fields need to be pursued, providing a unified approach to modeling, discretization, and iterative computation processes.PurposeThis study aims to achieve discrete and iterative solutions for multigroup neutron diffusion equations and neutron transport equations, considering the strong coupling between neutronics and thermal-hydraulics.MethodsFirstly, based on the open-source computational fluid dynamics (CFD) platform OpenFOAM, the finite volume method (FVM) was employed to discretize the control equations for neutron diffusion and neutron transport using the Gauss theorem. Then, the discrete ordinates method was applied to the discretization of the neutron transport equation for spatial angular discretization, and FVM was used to discretize both neutron diffusion and neutron transport equations spatial variables whilst the multigroup method was employed for discretizing energy variables, and implicit Euler method was utilized for discretizing time variables. Finally, neutron diffusion was verified using three benchmark cases, i.e., two-dimensional International Atomic Energy Agency (IAEA), three-dimensional IAEA, and three-dimensional LMW, to validate the effectiveness of the developed program, and neutron transport was verified using various benchmark cases including IAEA, TAKEDA, and C5G7.ResultsThe verification results for the two-dimensional IAEA benchmark show excellent agreement, with a maximum error of 1.1% in normalized power. The three-dimensional IAEA benchmark results align closely with reference values, showing a maximum error of 3.4%. For the three-dimensional LMW benchmark, the total power at 20 s is slightly underestimated, with a maximum error below 2%. The IAEA criticality benchmark results show region-averaged flux and effective multiplication factor deviations of 6.9% and 22×10-?, respectively. The TAKEDA benchmark confirms the program's accuracy in three-dimensional problems, with effective multiplication factor, neutron flux, and control rod worth matching reference values. The C5G7 benchmark validates the FVM-based transport algorithm's strong geometric adaptability and ability to solve both uniform and non-uniform neutron physics problems accurately.ConclusionsFVM-based neutron diffusion and transport algorithms developed in this study lay the foundation for the future simultaneous solution of conservation equations for physical and thermal multi-physics fields under a unified programming framework. The integrated verification of neutron diffusion and transport programs underscores the reliability and flexibility of the FVM in accurately solving complex neutron transport and diffusion scenarios, providing a pathway for enhancing precision and computational efficiency in nuclear engineering simulations under a unified programming framework.

BackgroundIn a series of startup physics tests, measuring the control rod worth is a critical means to determine whether the actual worth of the control rods matches the design values. This test ensures that the reactivity of the reactor can be precisely controlled through the control rods, thereby ensuring the safe operation of the reactor. Traditional methods for this measurement include the boron dilution method and the dynamic rod worth measurement method. Although these methods are now widely used in nuclear power plants (NPP), there is still potential for further improvement in both safety and economic performance. Subcritical control rod worth measurement does not require equipment transformation and on-site operations, which makes it easier to implement whilst control rod worth measurement under deep subcritical conditions is totally a different technique with respect to traditional control rod worth measurements, which changes the reactor condition from the Low Power Physics Test (LPPT) window after reaching criticality to the Criticality Approach Test (CAT) window before reaching criticality. The test conditions vary from near-critical condition to deep subcritical condition, making the core much safer.PurposeThis study aims to minimize the risk of core re-criticality during control rod withdrawal by measuring control rod worth within existing test windows without occupying the critical path.MethodsSubcritical control rod worth measurement was implemented within the window of startup physics tests, saving outage time and improving the economic efficiency of the power plant, hence no additional work was required for subcritical control rod worth measurement test, except for collecting relevant data while measuring the worth of control rods during the test. Two functional modules, namely the spatial correction factor calculation module and the data processing and display module were developed for subcritical control rod calibrating system. Under deep subcritical conditions, the traditional point reactor model was no longer applicable due to the significant impact on neutron flux distribution caused by the external neutron sources, therefore, a different approach was adopted to calculate the effects of external neutron sources on neutron flux distribution under deep subcriticality by carrying out a spatial correction of count rate to ensure a linear relationship between the corrected count rate and the subcriticality. Finally, two verification tests of subcritical control rod worth measurement were conducted on the AP1000 reactors at Sanmen Nuclear Power Plant (NPP), the count rate of the source range detector and reactor condition data were collected, and processed for quality improvement and spatial correction of count rate.ResultsVerification results show the linearity of the corrected count rate achieved is above 0.999, and the maximum subcriticality provided is approximately 0.1, indicating that the experimental conditions are in a deep subcritical state. All sets of control rod worth values meet the acceptance criteria requirement of a relative deviation of 10% or an absolute deviation of 75 pcm.ConclusionsThe results met the acceptance criteria of control rod worth, providing preliminary verification of the accuracy and reliability of calculation system under deep subcritical conditions.

BackgroundAccurate prediction of the coefficient of heat transfer (HTC) under extremely high parameter conditions in nuclear reactors is crucial for the design and operation of reactors, but the HTC is influenced by many factors, and there are issues such as unclear physical model and lack of experimental data. Traditional empirical relations often struggle to meet the demands of high-precision numerical calculations. Machine learning algorithms can effectively address the complex nonlinear problems, but some results do not conform to physical laws.PurposeThis study aims to propose a physical information machine learning (PIML) algorithm model that can calculate thermal parameters more accurately.MethodsFirstly, HTC experimental data were collected from a circular tube and subjected to preprocessing. Then, the HTC model was developed by combining the Jens-Lottes formula and the Thom formula with Multi-layer Perceptron (MLP), Backpropagation Neural Network (BPNN), and Random Forest (RF). Following this, the preprocessed data were partitioned into training and testing sets, with the training set utilized for model training and the testing set employed for model validation. Finally, six algorithms in the HTC models were evaluated and compared against empirical correlations.ResultsEvaluation results show that the calculation accuracy of Jens-Lottes formula combined with RF in the HTC model is the highest, with average relative error of predicting experimental data of 3.17%. The expandable range of the model accounts for 63.6% of the total applicable range, demonstrating good extrapolation capabilities. At the same time, using the PIML algorithm significantly enhances the computational accuracy of the physical model. The model based on the Jens-Lottes relationship combined with RF reduces the relative error of evaluation by 24.5% compared to the empirical relationship.ConclusionsThe PIML algorithm proposed in this study provides a framework for a high precision calculation model for HTC. It also provides a reference for expanding the scope of application.

BackgroundIn case of transient changes or minor accidents during reactor operation, the fuel temperature may temporarily exceed the critical threshold, thus forming bubbles on the fuel plate. Bubbling can significantly affect the temperature distribution and mass flow balance in rectangular channel of the fuel plate, which may lead to the rupture of the fuel plate and even the damage of the whole reactor core. The phenomenon of bubbling in plate-type fuel assemblies within nuclear reactors includes fission gas bubbles and solid bubbles.PurposeThis study aims to investigate the effects of air gap on the flow and heat transfer behavior in rectangular channel of fuel plate during bubbling conditions.MethodsFirstly, a fuel plate and two adjacent flow channels were selected as the calculation domain, and Fluent software with dynamic mesh technology was utilized to simulate gas bubbling and solid bubbling phenomena within nuclear reactor fuel plates. Then, the dynamic mesh was employed to accurately adapt to the geometric changes during bubble formation and development, and the Realizable k-ε turbulence model was used to handle complex fluid dynamics, with boundary conditions set as inlet velocity and outlet pressure to reflect real operational environments. Finally, the differences between fission gas bubbling and solid bubbling were compared, and all solid surfaces were designated as no-slip and adiabatic, enhancing the predictions of interactions between heat transfer and fluid flow.ResultsThe findings reveal that gas bubbles cause a local increase in temperature, with the heat flux around the bubbles tripling, though the overall heat flux of the fuel plate remains largely unchanged. The formation of bubbles locally enhances heat transfer capability by approximately 10%, with a 4% increase in heat flux on the bubble side. Under conditions of high flow rates, the presence of bubbles leads to a significant pressure difference across the fuel plate, causing deformation of the fuel plate and potentially leading to the blockage of the flow channel.ConclusionsResults of this study provide significant references for the design and safety assessment of nuclear fuel plates, highlighting the importance of considering the effects of gas bubbling on thermal-hydraulic characteristics in the design and operation of nuclear reactors.

BackgroundHelical coiled tube steam generator is the core equipment for energy transfer in a liquid metal fast reactor (LMFR), which transfers the heat released from the core on the primary side to the working mass on the secondary side, generates steam and pushes the turbine to do work. The stability and safety of its operation have a crucial impact on the operational safety, economy and reliability of nuclear power plants.PurposeThis study aims to propose a numerical simulation method using computational fluid dynamics (CFD) software for the coupled heat transfer calculation of two-phase fluids in the steam generator of LMFR.MethodsFirst of all, a three-dimensional numerical model of coupled primary and secondary heat transfer in the steam generator of LMFR was constructed, and the correlation equations of liquid metal and water-vapor variability were established based on the OECD (The Organisation for Economic Co-operation and Development) physical property handbook and the NIST (National Institute of Standards and Technology) database. Then, the Lee phase transition model was used to calculate the mass transfer between the two phases during the evaporation of water-vapor on the secondary side. Finally, the lead-bismuth fast reactor was taken as an object, the coupled heat transfer characteristics between the primary and secondary sides of the steam generator under different primary-side inlet parameters were investigated and compared with the conventional water reactors.Results & ConclusionsThe results show that, under the same conditions, compared with the traditional water reactor, the wall heat flux between the primary and secondary sides is significantly increased when lead-bismuth liquid metal is used in the primary side, and the peak heat flux can reach 1 439.97 kW?m-2, which is 5~6 times higher than that of the corresponding value of the water reactor, which leads to a significant intensification of the vapor evaporation process in the tube of the secondary side, and the volumetric vapor volume fraction rate rises sharply. Simutaneously, the along-track heat flux distribution between the primary and secondary sides is more heterogeneous, which leads to an increase of the vapor volume fraction rate. Meanwhile, the relative deviation of the heat flux distribution along the heat flux is 3~4 times larger than the corresponding value of water reactor. With the increase of the inlet lead-bismuth temperature on the primary side from 350 ℃ to 450 ℃, the wall heat flux between the primary and secondary sides increases, and the corresponding peak heat flux increases from 950.7 kW?m-2 to 1 439.97 kW?m-2. The distribution of the along-range heat flux between the primary and secondary sides is more inhomogeneous, and the inhomogeneity is increased by 20%.

BackgroundFor high-fidelity simulations of fluid dynamics in molten salt reactor (MSR), even though a supercomputer is able to suppress the period of each simulation, the consequent expense is still prohibitively costly. A possible way to overcome this limitation is the use of Reduced Order Modelling (ROM) techniques.PurposeThis study aims to evaluate the accuracy of the ROM methods for reconstructing the velocity and pressure fields.MethodsTwo ROM methods based on the Proper Orthogonal Decomposition (POD) with both Galerkin projection, namely FV-ROM (ROM based on Finite Volume approximation) and SUP-ROM (ROM with supremizer stabilization), were established for fluid dynamics of MSR. Then, both methods were tested on the unsteady cases of liquid-fueled molten salt reactor (LFMSR) for comparison and applicability analysis.ResultsThe FV-ROM demonstrates notable advantages in both velocity prediction and computational efficiency. For laminar and turbulent transient simulations, the average velocity L2 relative errors are less than 0.5% and 0.6%, respectively, with acceleration ratios of approximately 1 500 and 1 000 times for single time steps. Conversely, the SUP-ROM scheme demonstrates significant prowess in pressure prediction, achieving remarkably low pressure average L2 relative errors of 0.20% and 0.38% for laminar and turbulent transient scenario, respectively.ConclusionsResults of this study indicate that combination of SUP-ROM and FV-ROM for fluid dynamics computations of MSR can significantly enhance computational efficiency and ensure reliability and accuracy of transient simulation.